Type of event: Study tour

Topic: Wood Products

Organization: Tropical Salvage, The Joinery.

Location: Portland, Oregon

Hosts: Kim Allchurch-Flick and Tim O'Brien (Tropical Salvage), Cassandra Jackson (The Joinery)

International Fellows: Richard Banda (Malawi), Fen-hui Chen (Taiwan), Temitope Dauda (Nigeria), Zhongyuan Ding (China), Ana Kanoppa (Brazil), Will Maiden (United Kingdom), Romain Matile (France),

WFI Staff: Shadia Duery / International Fellowship Manager

Many different products can be produced from wood, from native or from planted forests. The utility of these products will depend on your needs. The range in the market is extensive, ranging from low-volume, high-quality home decor products that utilize unique designs to high-volume, low-cost lumber. On our final group study tour, the International Fellows set out to investigate this range of products.

Raw material is from salvaged wood. Tropical Salvage has never felled a single tree.

In the morning, our first stop was a visit to Tropical Salvage, a store dedicated to selling furniture hand-crafted in Indonesia using hardwoods salvaged from rivers, volcanic lahars, and land conversion. Tropical Salvage prides themselves on having never cut down a single tree to create their products. The company has created local jobs in Indonesia and directly employs 45 people in Jepara in north-central Java. Furthermore, part of the sales revenue is used to buy small areas of land to plant and conserve tropical forest. Tropical Salvage’s target market is consumers concerned about good values in the supply chain and focused on Fair Trade and sustainability. They also look towards consumers who appreciate the natural beauty present in timber, as each piece of furniture is unique. Many people in Portland are attracted to buy this variety of custom-made products using local design. The story of not exploiting new areas of forest whilst contributing to protecting biodiversity and improving the welfare of people in Indonesia give the furniture store a positive message for the consumer.

At Tropical Salvage, wood products are made with a “no waste” attitude

and an appreciation of variation in natural appearance.

|

| The Joinery creates beautiful, quality wood furniture of modern and classic design that you can use for a lifetime. |

The Joinery recycles their scrap lumber and sawdust into wood briquettes

that they donate to the local community. (left)

Each piece of furniture crafted at The Joinery is wholly built by a single woodworker

and receives the company plaque and builder signature. (right)

Our third and final stop on the study tour was to the US institution that is Home Depot. Here, our aim was to see how timber products are sold to the American consumer. In contrast to Tropical Salvage and The Joinery, the timber sold here is aimed at structural purposes, and visual aesthetics of the timber are secondary in comparison to structural performance.

Home Depot stocks sustainably-sourced wood products (left).

Much of the engineered timber products on sale are domestically produced (right).

Most homes in the US are manufactured from timber. Timber is relatively inexpensive and allows for quick erection of buildings. The timber products on sale at Home Depot cover all aspects required within construction, from structural timbers to engineered wood products. Douglas fir makes up most of the timber used for structural purposes. The timber has excellent load-bearing qualities and is easily workable. Douglas fir has a large internal demand within North America and is also in demand globally as a high-grade structural wood. Home Depot stocks a range of timber products for the interior studwork of a home. Here the primary species used is Western hemlock, noted for its low resin content and strong nail and screw-holding ability. This makes it the ideal choice for finishing the interior of a property. Where timber is required for an outdoor situation, Western Red Cedar provides a naturally rot and insect resistant timber that has historically been used for exterior cladding, roofing shingles, and picket fencing. Home Depot stocks timber from certified sources under the Sustainable Forestry Initiative. This helps to ensure that timber comes from forests managed in a manner which is less damaging to the environment

In addition, products such as plywood and oriented strand board are sold. These manufactured timber products are a crucial element in the construction of US homes, providing a lightweight solution to covering large spans within the framework of a structure.

International Fellows' Thoughts and Perspectives

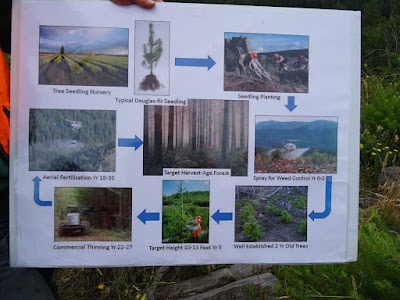

Both Tropical Salvage and The Joinery market their products to a high-end, niche market. The products tell a story of supporting small communities in Indonesia and specialist timber producers in the US, respectively. Customers who purchase these wood products are willing to pay a premium to purchase an item of furniture with this provenance. In contrast, Home Depot sells large quantities of timber at relatively low prices. Here, consumers are maybe more concerned with getting value for their money in the products they purchase. It has been interesting as, over the course of the Fellowship, we have seen the complete process required in the timber industry, from seedling production, tree farm management, and processing within sawmills. Visiting Home Depot has allowed us to see the final products these processes aim to achieve.

|

| International Fellows in their Portland uniform (left to right): Ana Kanoppa from Brazil, Will Maiden from Britain, and Fen-hui Chen from Taiwan |